Asimov Unveils AI-Powered AAV Edge Platform for Gene Therapy Design and Manufacturing

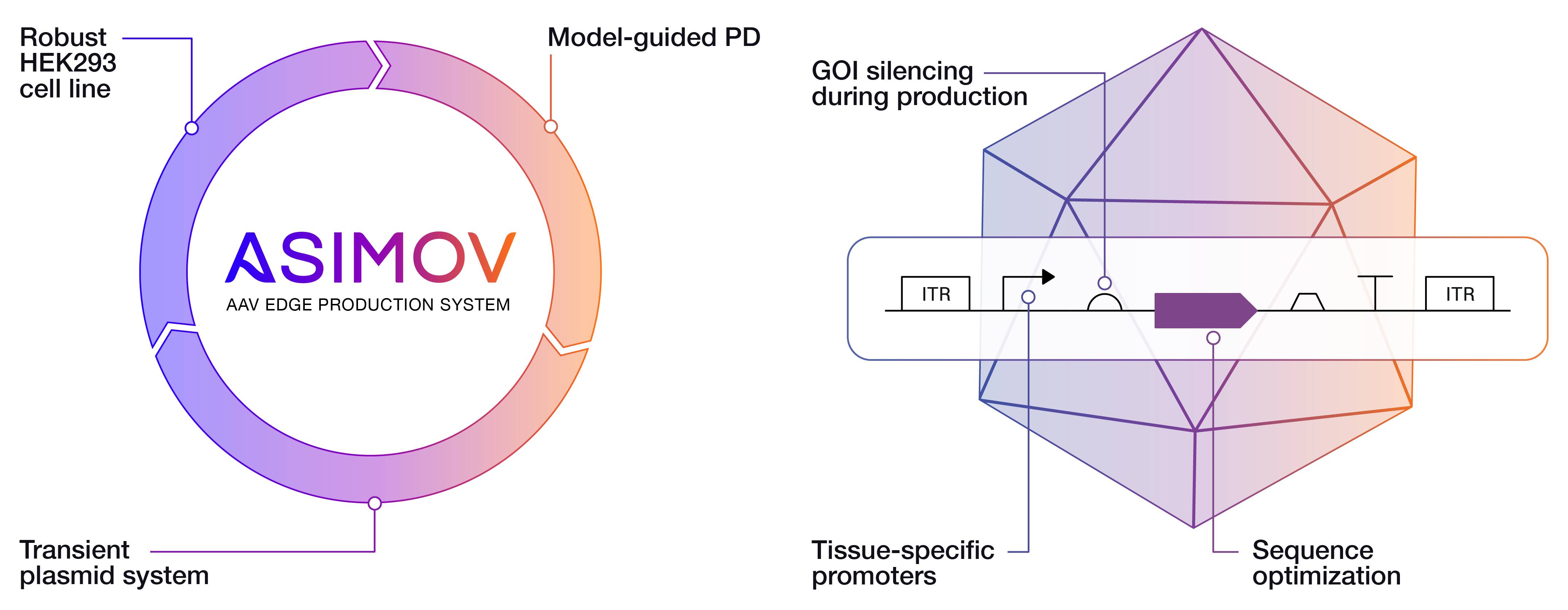

Asimov, a leader in AI-driven synthetic biology, has launched AAV Edge, an AI-powered suite of tools for gene therapy design and manufacturing.

As reported in their announcement on Twitter, AAV Edge is the first comprehensive platform offering end-to-end optimization for adeno-associated virus (AAV) manufacturing, addressing critical challenges in safety, manufacturability, and cost. With over 500 gene therapies in development, this platform aims to streamline processes and make treatments more accessible to patients.

AAV Edge was designed to enhance every step of gene therapy production by combining advanced AI with validated biological components. It allows developers to design precise, tissue-specific therapies while optimizing production for higher yields and reduced toxicity.

A key feature is the AI-designed tissue-specific promoters (TSPs), validated in preclinical studies, which enable targeted gene expression. Leveraging multi-omics data, these promoters restrict gene expression to intended tissues. ]Asimov reports their promoters exhibit over a 200-fold dynamic range in expression between target and off-target tissues, minimizing side effects.

Asimov's AAV Edge production and payload design

The platform also includes a DNA optimization tool that enhances gene expression. Using their proprietary Kernel software—a computer-aided design tool for gene sequence optimization—they achieved up to a 7x increase in transgene expression in HEK293T cells. Additionally, Asimov’s genetic circuits silence genes of interest during production to reduce toxicity without compromising therapeutic function.

On the production side, AAV Edge features a suspension-adapted, clonal HEK293 cell line that is GMP-banked and optimized for AAV production. Combined with two-plasmid system, it achieves unconcentrated bioreactor titers up to E12 viral genomes per milliliter. Tested across multiple scales, this system is said to be ready for transfer to commercial production settings.