Brinter AM to Launch 3D Bioprinter to the International Space Station

Brinter AM Technologies Oy has been selected to provide a 3D bioprinter for a European Space Agency (ESA) project aimed at advancing tissue manufacturing capabilities on the International Space Station (ISS). The Finnish company will supply its bioprinter, Brinter Core, to Redwire Space NV, which is spearheading the project to develop the 3D-BioSystem Facility under the ESA Exploration Programme.

The project is focused on utilizing microgravity conditions aboard the ISS to study the effects on human tissue and develop technologies that can maintain astronaut health during long-term missions. The initiative also seeks to translate these findings into benefits for human health on Earth.

Adapting 3D Bioprinting for Space

Brinter AM Technologies will adapt its Brinter Core bioprinter to meet the stringent requirements of space technology. The bioprinter will be integrated into the 3D-BioSystem Facility, which will operate in the ISS's Columbus module. This integration will enable the production of 3D-printed cell constructs in orbit, allowing researchers to study how microgravity influences tissue formation and regeneration.

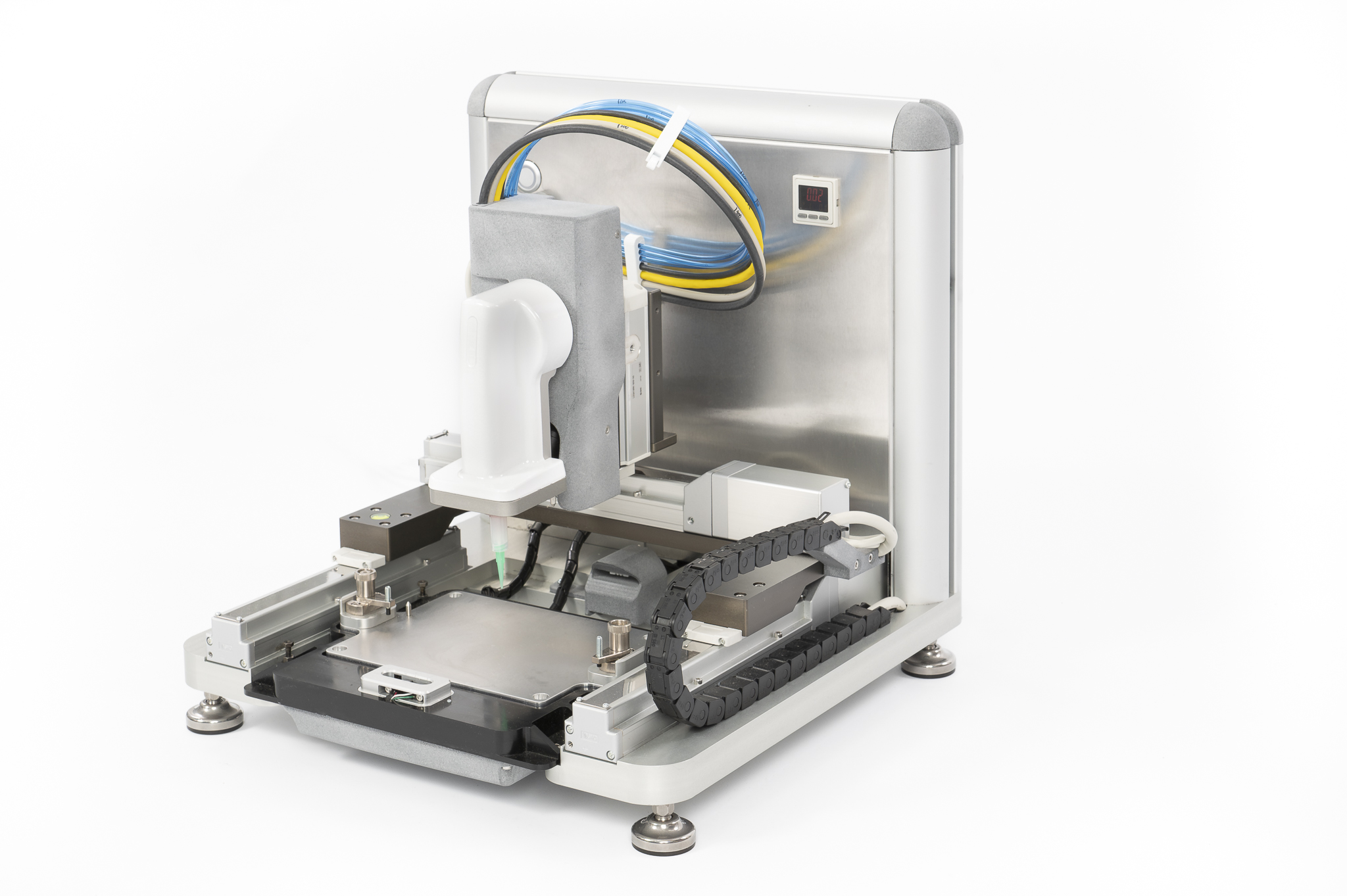

The image shows the Brinter Core, the existing commercial version that served as the foundation for developing the space-adapted model, which is still in progress and not yet available for viewing.

Microgravity provides a unique environment for 3D bioprinting because it allows cells to grow and assemble into complex three-dimensional structures without the need for supporting scaffolds, which are typically required on Earth to counteract the effects of gravity. This capability could significantly enhance the development of human tissue models and expand the potential applications of bioprinting in space.

Supporting Human Space Exploration

The project aims to advance bioprinting technologies that could become crucial for future human space exploration. By enabling the creation of tissue-like constructs to replace damaged tissues or produce personalized drugs, the technology could support medical treatments and increase crew autonomy during long-duration missions.

Tomi Kalpio, CEO of Brinter AM Technologies Oy

Tomi Kalpio, CEO of Brinter AM Technologies Oy, commented:

“Bioprinting technologies have great potential to support medical treatment in space and increase the crew's autonomy on long-term missions. Astronauts could create tissue-like constructs to replace damaged parts of their bodies, for example, to treat skin burns or bone damage, or print personalized drugs ideally matched to the person.”

The ability to bioprint tissues in microgravity could be especially valuable for missions beyond low Earth orbit, where a quick return to Earth is not feasible. This capability would help astronauts manage medical emergencies and conduct scientific research, such as drug development and toxicology testing, more independently.

Harnessing Microgravity for Advanced Tissue Research

The microgravity environment aboard the ISS offers unique advantages for 3D bioprinting. In the absence of gravity, cells exhibit unrestricted growth and can form complex three-dimensional aggregates, providing new opportunities for tissue and organ modeling. This environment also facilitates the cultivation of various 3D cell structures, such as organoids, tissue explants, and cell matrixes, enabling researchers to investigate the effects of microgravity, radiation, and other spaceflight factors on different tissues.

The research conducted under this program will be critical for understanding the bioengineering and biofabrication requirements needed to create highly viable and functional tissues, such as vascularized and innervated constructs. Insights gained from these studies could lead to further optimization of 3D bioprinting and cell and tissue engineering technologies, both in space and on Earth.

"This project has a lot of synergy with the research and development work we have done in the last five years related to our mesh biomods, and our team is eagerly waiting to take the next step towards the moon," added Kalpio.

Topics: Tools & Methods